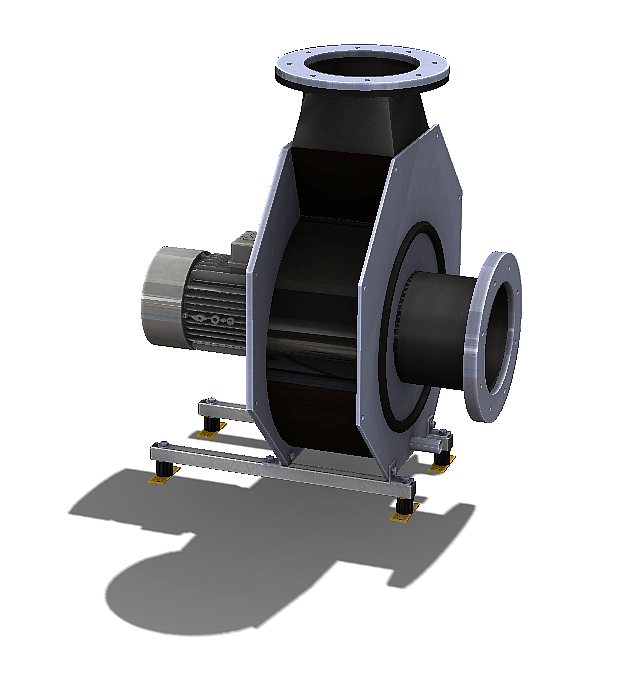

VAKUTEC® - Rohrradialventilatoren SRN3, SRM4, SRH4

Sizes and performance range:

The centrifugal tube fans in the above series are available in various sizes. The sizes are graded in standardised steps and enable the controlled extraction of atmospheres. The volume flow-pressure diagrams on the following pages are used for more precise dimensioning. The use of frequency controllers makes it possible to realise any speed, regardless of the nominal speed of the motors, so that the extraction performance can be adapted to the actual requirements. The maximum speed is limited by the material properties.

Drives and motors:

The impeller is driven directly by a motor built into the fan hub. This design means that the motor is completely separated from the aggressive exhaust air. The drive is an externally cooled three-phase squirrel cage motor with protection class IP55. On request, the fans can also be supplied with explosion-proof three-phase motors.

Detailed catalogue with characteristic curves and dimension sheets

Detailed catalogue with characteristic curves and dimension sheets

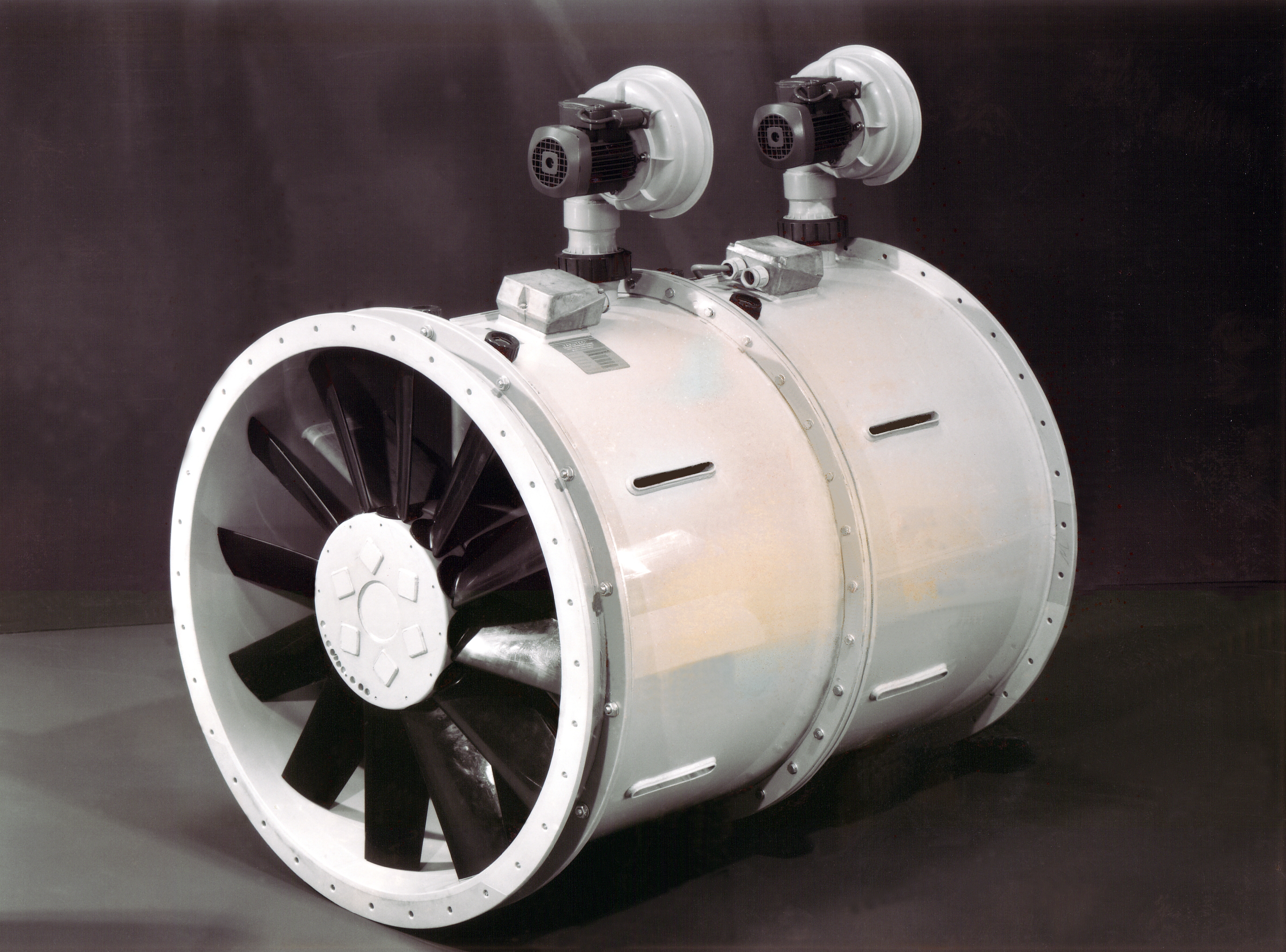

VAKUTEC® - Axial- and tube radial fans

Scheidt Ventilatoren GmbH has been offering a wide range of fans for all conceivable applications since 1984. Each of these fans, which are marketed under the VAKUTEC® brand name, is characterised by its corrosion-resistant plastic construction. This means that they can also be used in the most demanding environments

Additional information: Subcategories of this page:

VAKUTEC® - Small and lightweight fans

Since 1984, Scheidt Ventilators GmbH has been offering a wide range of fans for all conceivable areas of application. Each of these fans, which are sold under the brand name VAKUTEC®, is characterized by its corrosion-resistant plastic construction. This means that it can also be used in the most demanding environments.

Additional information: Subcategories of this page:

small radial fan SK

light duty industrial fan VL

VAKUTEC® - smal radial fan SK

Sizes and performance range

VAKUTEC small radial fan with the type designation SK7 and SK11 are single-suction, corrosion-resistant centrifugal fans. Two different sizes are manufactured:

- The SK7 with an intake diameter of 75mm

- The SK11 with an intake diameter of 110mm

Areas of application include small digestories, chemical cabinets, chemical containers, table suction systems, etc. This enables the controlled extraction of atmospheres up to a volume flow of 370m³/h and a total pressure increase of up to 450Pa.

The sound pressure level at a distance of 1 meter from the fan with connected suction and pressure lines is, depending on the motor manufacturer, motor type (AC and three-phase current / Ex motors) with connected suction and pressure sides:

- for type SK7 ~52-58dB(A)

- for type SK11 ~55-61dB(A)

Materials:

The impellers for both types are manufactured from PP using injection moulding. The same material and process is used for type SK7, while the housing of type SK11 is made of PVC, PPs or PE in welded construction.

Housing positions:

Due to the compact design, combined with very low weight

SK7 ~4.5 kg (with explosion-proof motor ~9.5 kg), SK11 ~5.5 kg (with explosion-proof motor ~10.5 kg), these centrifugal fans can be easily installed and mounted anywhere. For designs A, B and D, the fan can be installed according to local requirements. Type C is manufactured in position GL360 as standard. As a special design, all positions can of course be manufactured for the GL direction of rotation.

Impellers:

The impellers of the types listed above are manufactured from polypropylene (PPs) by injection moulding or in welded design. If required, the impellers can also be supplied in steel with a corrosion-resistant coating. They are fitted with 6 backward-bent blades as standard.

Drives and motors:

The impeller is driven directly by a motor flanged to the housing. The drive is an externally cooled 60W AC motor of type B5, protection class IP54, 220V, 50Hz, 2800rpm. However, the fans can also be supplied with three-phase and explosion-proof motors on request.

The fans in the SK series have ATEX certification for Zone CE Ex II 2(3) G T4.

Detailed catalogue with characteristic curves and dimension sheets

VAKUTEC® - Lightweight radial fan VL

Sizes and performance range:

VAKUTEC® - lightweight radial fans with the type designation VL are single inlet corrosion-resistant blowers. Five different sizes are manufactured:

- VL-164 with an inlet diameter of 160mm

- VL-184 with an inlet diameter of 180mm

- VL-204 with an inlet diameter of 200mm

- VL-254 with an inlet diameter of 250mm

- VL-314 with an inlet diameter of 315mm

These centrifugal fans are used to extract exhaust air laden with chemicals, such as those found in chemical laboratories or electroplating. Controlled extraction of atmospheres up to a volume flow of 4,000 m³/h and a total pressure increase of up to 1,500 Pa is possible. The performance curves for the above-mentioned types are listed on the following pages.

The design of the fans with intake and discharge nozzles in the centre of the axis enables installation regardless of the direction of rotation of the impeller. The position of the fans can be adapted to the location by changing the mounting rails (loosening 4 screws). The possible positions can be found in the dimension sheet on the last page.

Materials:

The enclosures are manufactured using a CNC machining centre from polypropylene (PP), flame-retardant polypropylene (PPs), polyvinyl chloride (PVC) and polyethylene (PE) and assembled in a solid welded construction. In accordance with the UVV, the housings are surrounded by splinter protection. The standard equipment includes four swing elements, sleeves on the suction and discharge connections and condensate connections. The supporting structure is designed with mounting rails made of galvanised steel.

Impellers:

The impellers of the types listed above are manufactured from polypropylene (PPs) by injection moulding or in a welded design. If required, the impellers can also be supplied in steel with a corrosion-resistant coating. They are fitted with 6 backward-bent blades as standard.

Drives and motors:

The impeller is driven directly by a standard motor flanged to the housing.

The drive is a three-phase cage rotor of type B5 with protection class IP55.

The characteristic curves shown in bold in the performance curves are directly affected by the standard speeds 1.000 / 1.500 / 3.000 rpm directly.

The other characteristic curves are achieved by a frequency converter (230V/50Hz supply voltage) mounted on the housing. When using the frequency inverter, the power of the fan can be infinitely adjusted by the operator.

Detailed catalogue with characteristic curves and dimension sheets

Deutsch (Deutschland)

Deutsch (Deutschland)  English (United Kingdom)

English (United Kingdom)