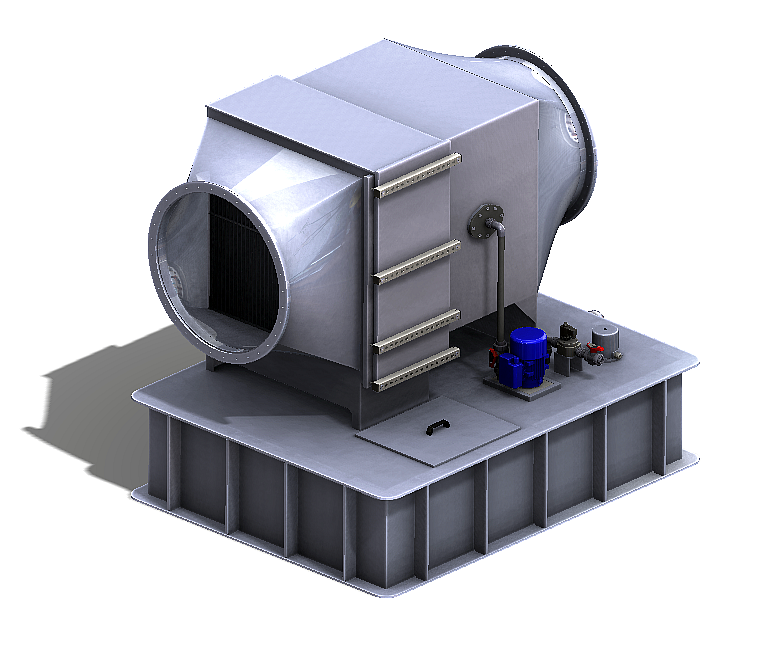

VAKUTEC® - short washer WH2

with and without Koagulator (Droplet enlarger)

General Information:

VAKUTEC® short scrubbers of type WH2 are primarily used when exhaust air needs to be cleaned of contaminants that have a high affinity for water and must be separated for environmental reasons. These impurities include, for example, hydrochloric acid vapors.

- Application: Mass transfer with high water affinity, hydrochloric acid vapours

- Features: Contact chamber, 2 droplet separator packages, coagulator optional

Sizes and performance range:

Short scrubbers in sizes from DN180 to DN1.250 for volume flows of 1.100 to 68.800m³/h are described below. VAKUTEC® type WH2 short scrubbers for larger volume flows must be designed separately.

Construction:

The droplet separator unit of the short scrubber is equipped with a quick-release fastener. The continuously fed double spray nozzle is located on a lance that is flange-mounted to the housing. This enables maintenance or inspection within a very short time. The installation direction of the droplet separator unit, right/left or upwards when viewed in the air direction, is adapted to the local conditions.

Materials:

The materials used depend on the specific physical and chemical loads that occur. Preferably, plastics such as PVC, PP and PVDF are used. In special cases, stainless steel profiles can also be used as droplet separator packages.

Technical data:

With a uniform flow, the short scrubber without coagulator enables 99% separation of a limiting droplet of approx. 15µ at a pressure loss of approx. 300Pa. With a coagulator, the separation efficiency increases to a limiting droplet of approx. 10µ at a pressure loss of approx. 450Pa.

(The measured efficiency of the separation efficiency of a boundary droplet under laboratory conditions with water at 20° C)

Detailed catalogue with characteristic curves and dimension sheets

Deutsch (Deutschland)

Deutsch (Deutschland)  English (United Kingdom)

English (United Kingdom)