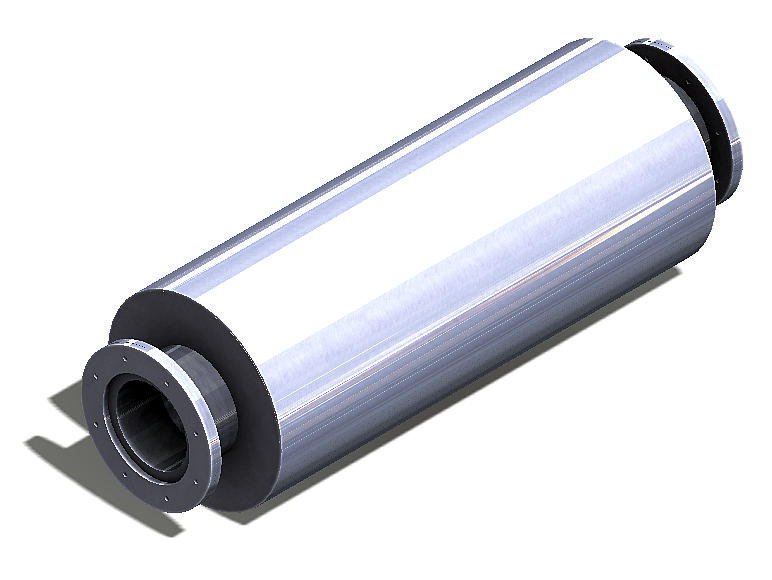

VAKUTEC® - pipe silencer RSD

For volume flows up to 4.080 m³/h

General information:

VAKUTEC® tubular silencers of types RSD075 to RSD400 are primarily used when noise emissions have to be reduced in accordance with directives such as „TA-Lärm“.

Sizes and performance range:

Pipe silencers in sizes up to DN400 for volume flows up to 4,080m³/h are described below. VAKUTEC® pipe silencers for larger volume flows must be designed separately.

Designation:

The pipe silencers are given the abbreviation RSD for splitter silencer as a general designation and the nominal diameter (075, 090, 110, 125, 140, 160, 180, 200, 224, 250, 280, 315, 355, 400) as an appendix.

Construction:

The design of the pipe silencer, or its connection to the intended pipework or duct system, is adapted to the local conditions. In the following, the silencers are shown in designs 1 and 2, with socket connection and with flanges. The design of the nominal diameters is based on the maximum permitted velocity of 9 m/s in the pipe.

How it works:

Absorption silencers are used. The sound energy penetrates the absorbent material and is converted into kinetic energy.

The movement of the fibrous material causes friction between the fibres. The kinetic energy is then converted into heat by the friction.

Materials:

The materials used depend on the specific physical and chemical loads that occur. Preferably, plastics such as PVC, PP and PVDF are used for the housing and the baffle frames. The baffles are made of sound-absorbing glass or mineral wool, which is additionally protected with sound-transparent film if necessary.

Technical data:

The VAKUTEC® baffle silencers of types RSD075 to RSD400 enable an insertion loss of 13 to 40 dB(A) at an octave centre frequency of 250Hz. The pressure loss to be taken into account is approx. 15Pa per metre.

Detailed catalogue with characteristic curves and dimension sheets

Deutsch (Deutschland)

Deutsch (Deutschland)  English (United Kingdom)

English (United Kingdom)