VAKUTEC® - Industrie-Ventilatoren

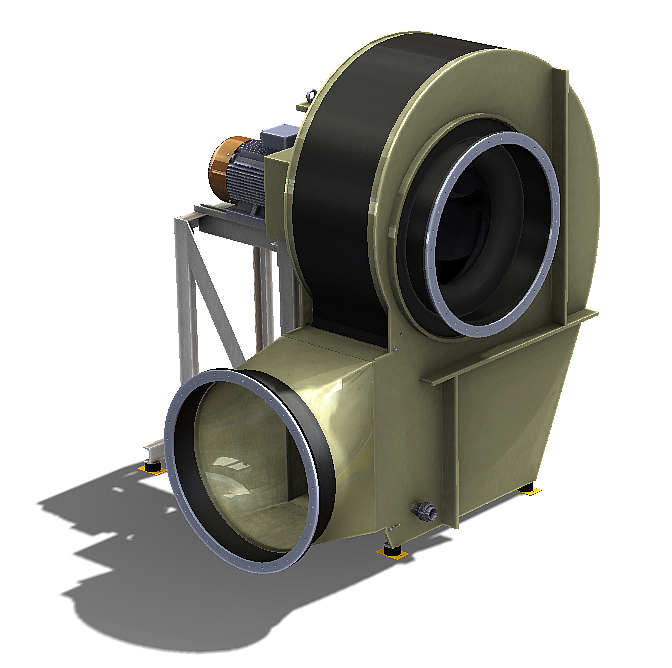

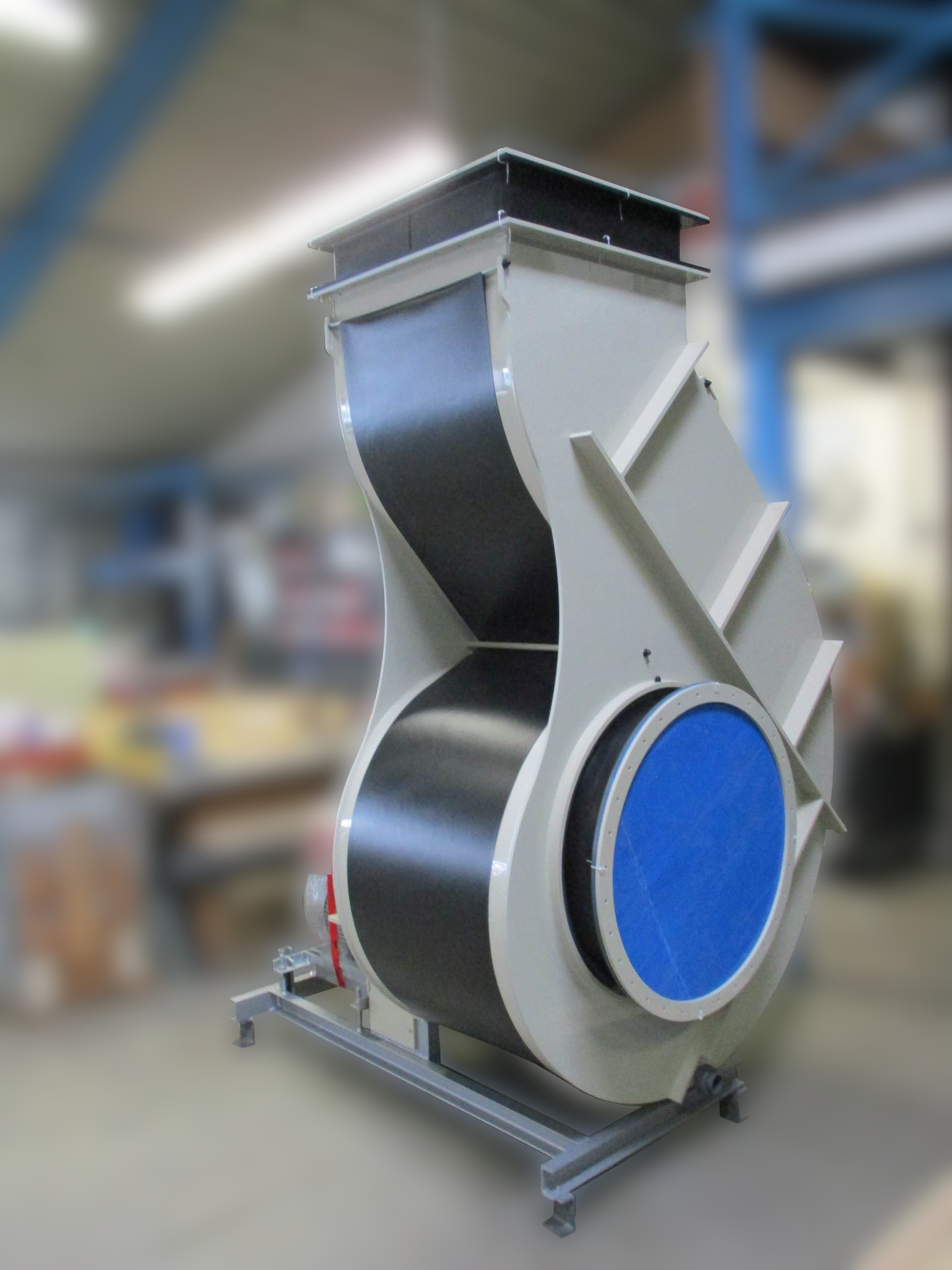

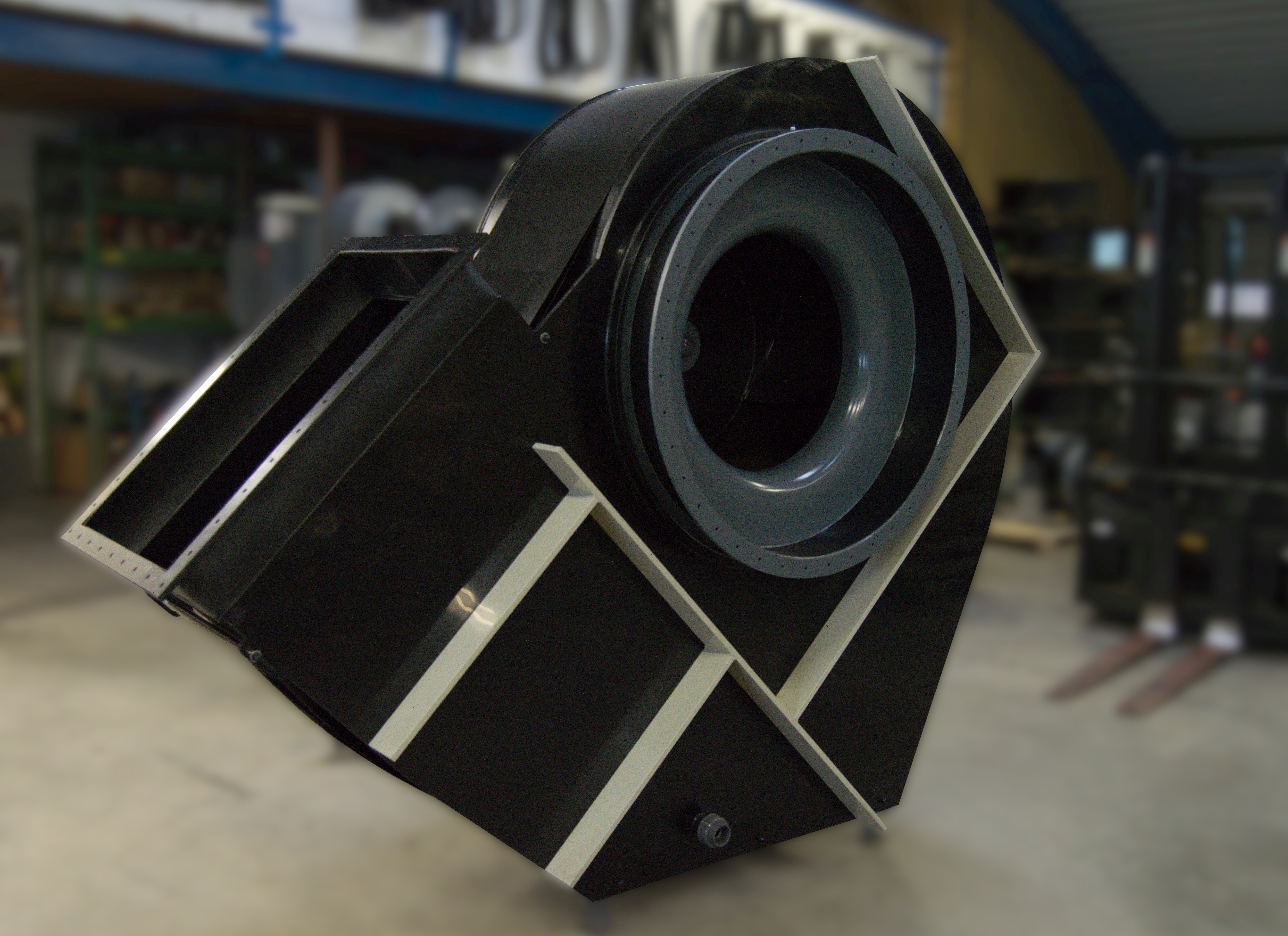

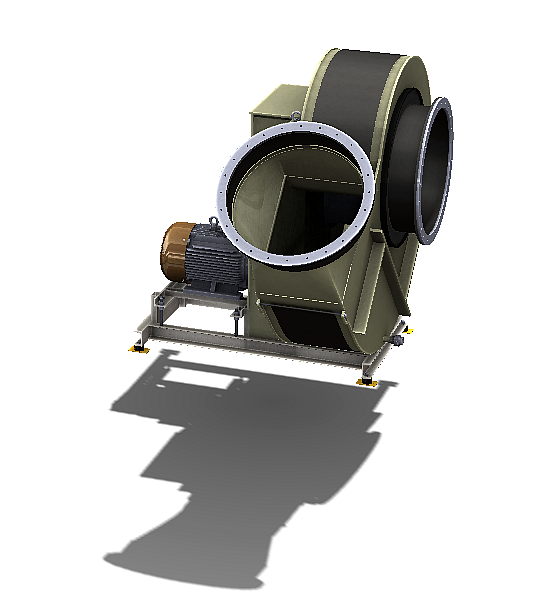

Since 1984, Scheidt Ventilators GmbH has been offering a wide range of fans for all conceivable areas of application. Each of these fans, which are sold under the brand name VAKUTEC®, is characterized by its corrosion-resistant plastic construction. This means that it can also be used in the most demanding environments.

For more information about our radial fans, please follow the other categories on the left

VAKUTEC® - Industrie-Ventilatoren

Since 1984, Scheidt Ventilators GmbH has been offering a wide range of fans for all conceivable areas of application. Each of these fans, which are sold under the brand name VAKUTEC®, is characterized by its corrosion-resistant plastic construction. This means that it can also be used in the most demanding environments.

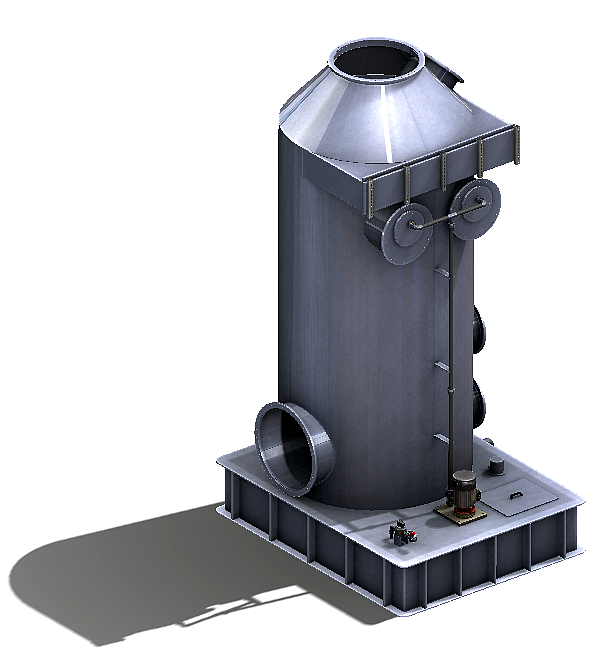

VAKUTEC® - packed air scrubber WV3

with droplet separator and Koagulator (Droplet enlarger)

General information:

VAKUTEC® type WV3 empty towers are primarily used when exhaust air is to be cleaned of contaminants that have a moderate to low affinity to water and must be separated for environmental protection reasons. These impurities include, for example, mixed acid vapours.

- Application: Mass transfer with moderate water affinity

- Features: 2m/s air velocity in the tower (WV320), 1m/s air velocity in the tower (WV310), 0.5m/s air velocity in the tower (WV305), integrated template, packing unit, counterflow spraying of the air flow in the tower, 2 droplet separator packages

Descriptions:

The designation WV3 defines a vertical scrubber that has a packing unit. The following two digits define the speed in metres per second. The speed in the tower is multiplied by 10 and, if the result is a single digit, is given a leading zero.

- WV320 - tower packing with an air velocity of 2 m/s in the tower

- WV310 - tower packing with an air velocity of 1 m/s in the tower

- WV305 - tower packing with an air velocity of 0.5 m/s in the tower

Sizes:

The following packed towers are described:

- WV320 - DN180 to DN1.000 for volume flows from 1.100 to 43.999m³/h

- WV310 - DN180 to DN710 for volume flows from 1.100 to 22.299m³/h

- WV305 - DN180 to DN1.000 for volume flows from 1.100 to 10.999m³/h

VAKUTEC® tower packings of type WV3 for larger volume flows must be designed separately.

Construction:

The droplet separator unit of the tower packing is positioned at the top of the column and fitted with a quick-release fastener. The continuously fed spray nozzles are located on lances that are flange-mounted to the tower. This enables maintenance or inspection within a very short time. The atomised liquid wets the packing and optimises the mass transfer. A receiver tank is integrated, which is equipped with quick filling, overflow, residual emptying, pump and manhole as standard. The air outlet after the droplet separator unit can be either horizontal or vertical.

How it works:

VAKUTEC® tower packings type WV3 work according to the principle of mass transfer in a counterflow process with packing. With the help of an upstream nozzle level, the tower packing and air flow are continuously sprayed. The impurities in the air are transferred to the sprayed scrubbing liquid due to the water affinity. The aerosols, carried by the air flow, then collide with the droplet separator packages. The drops of liquid are guided to the inner surfaces of the profile by the curvature of the profile, are diverted downwards by gravity and return to the storage container. The droplet separator unit can optionally be equipped with a coagulator. The coagulator is placed in front of the droplet separator units and thus enlarges the very small droplets so that they can then be separated in the separator unit.

Materials:

The materials used depend on the specific physical and chemical stresses that occur. Plastics such as PVC, PP and PVDF are preferably used. In special cases, stainless steel profiles can also be used as mist separator packages.

Technical data:

With a uniform flow, the packing tower with droplet separator and coagulator enables 99% separation of a limit drop of approx. 15µ, with a coagulator the separator performance increases to a limit drop of approx. 10µ. The pressure loss to be taken into account is listed on the dimension sheets.

(The measured effectiveness of the separation efficiency of a boundary drop under laboratory conditions with water at 20° C)

Detailed catalogue with characteristic curves and dimension sheets

VAKUTEC® - air scrubber WV2

without packing with vertical droplet separator and Koagulator (Droplet enlarger)

General information

VAKUTEC® type WV2 empty towers are primarily used when exhaust air needs to be cleaned of impurities that have a high affinity to water and must be separated for environmental protection reasons. These impurities include, for example, hydrochloric acid vapours.

- Application: Mass transfer with high water affinity

- Features: 2m/s air speed in the tower, integrated template, counterflow spraying of the air flow in the tower, 2 droplet separator packages

Sizes and performance range

Emptying towers in sizes from DN180 to DN1.000 for volume flows from 1.100 to 43.999m³/h are described below. VAKUTEC® WV2 empty towers for larger volume flows must be designed separately.

Construction

The droplet separator unit of the empty tower is positioned at the head of the column and equipped with a quick-release fastener. The continuously fed spray nozzles are located on lances that are flange-mounted to the tower. This enables maintenance or inspection within a very short time. A storage tank is integrated, which is equipped with quick filling, overflow, residual emptying, pump and manhole as standard. The air outlet after the droplet separator unit can be either horizontal or vertical.

How it works

VAKUTEC® WV2 empty towers work according to the principle of material transfer in a counterflow process. The air flow is continuously sprayed with the aid of an upstream nozzle level. The impurities in the air are transferred to the sprayed scrubbing liquid due to the high water affinity. The aerosols, carried by the air flow, then collide with the droplet separator packages. The drops of liquid are guided to the inner surfaces of the profile by the curvature of the profile, are diverted downwards by gravity and return to the storage container. The droplet separator unit can optionally be equipped with a coagulator. The coagulator is placed in front of the droplet separator units and thus enlarges the very small droplets so that they can then be separated in the separator unit.

Materials

The materials used depend on the specific physical and chemical loads that occur. Preferably, plastics such as PVC, PP and PVDF are used. In special cases, stainless steel profiles can also be used as droplet separator packages.

Technical data

With a uniform flow, the empty tower including droplet separator and coagulator enables 99% separation of a limiting droplet of approx. 15µ at a pressure drop of approx. 400Pa. With a coagulator, the separator performance increases to a limiting droplet of approx. 10µ at a pressure loss of approx. 500Pa.

(The measured efficiency of the separation efficiency of a boundary droplet under laboratory conditions with water at 20° C)

Detailed catalogue with characteristic curves and dimension sheets

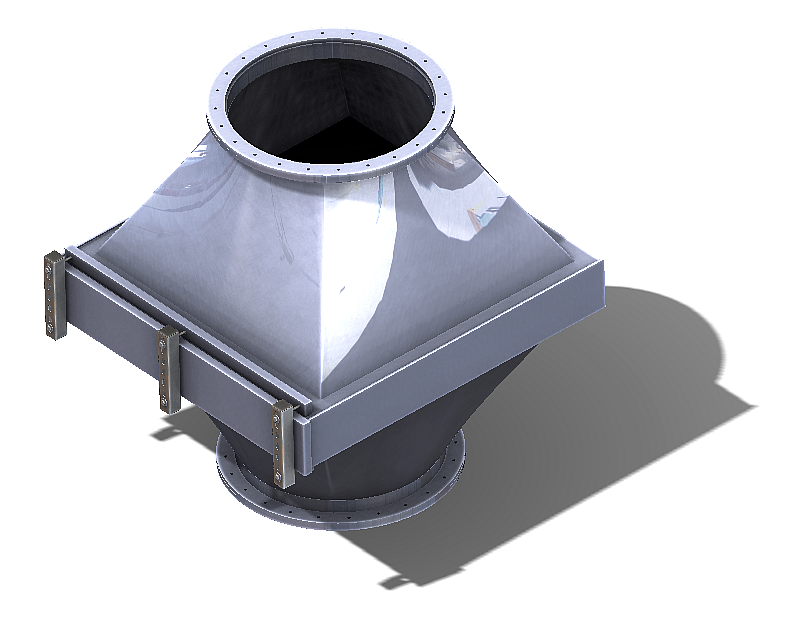

VAKUTEC® - droplet separator WV1

with and without Koagulator (Droplet enlarger)

General information

VAKUTEC® droplet separators type WV1 are primarily used when aerosols have to be separated for environmental protection reasons.

- Application: Aerosol separation

- Features: 2 droplet separator packages, coagulator optional

Sizes and performance range

Droplet separators in sizes from DN180 to DN1,250 for volume flows of 1,100 to 68,800m³/h are described below. VAKUTEC® mist eliminators of type WV1 for larger volume flows must be designed separately.

Construction

The droplet separator is designed with a quick-release fastener. This enables maintenance or inspection within a very short time. The installation direction of the droplet separator unit, right/left or upwards when viewed in the air direction, is adapted to the local conditions.

Deutsch (Deutschland)

Deutsch (Deutschland)  English (United Kingdom)

English (United Kingdom)