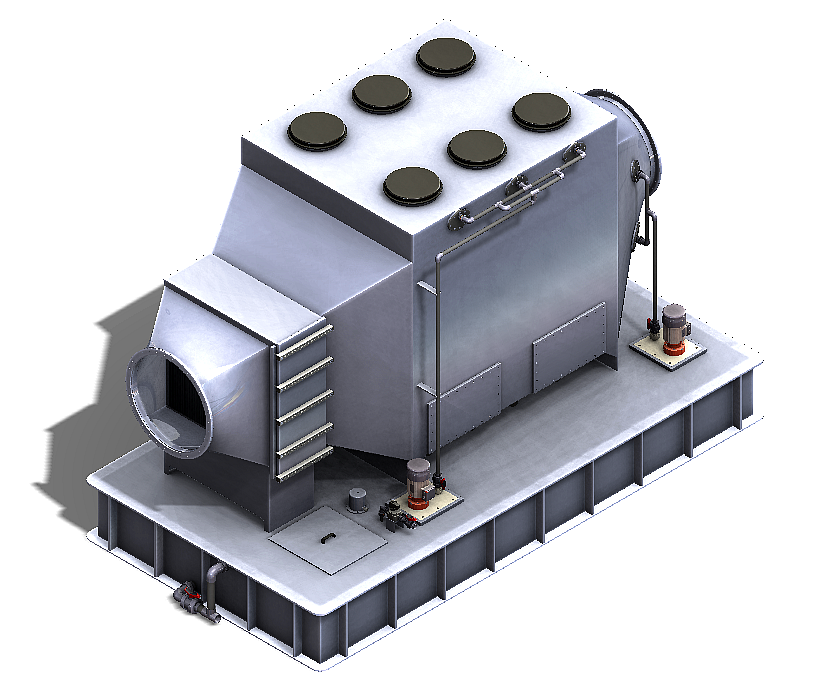

VAKUTEC® - air washer with Packing unit WH5

with and without Koagulator (Droplet enlarger)

General information

VAKUTEC® type WH5 air washers are used when exhaust air needs to be cleaned of impurities that do not have a high affinity for water and must be separated for environmental protection reasons. This air washer is primarily used for exhaust air that contains mixed acids or is moderately contaminated with NOx.

- Application: Mass transfer with moderate water affinity, mixed acid mist and moderate NOx contamination

- Features: Packing chamber, 2 droplet separator packages, coagulator optional

Sizes and performance range

Air washers in sizes from DN180 to DN1.250 for volume flows of 1.100 to 68.800m³/h are described below. VAKUTEC® air washers of type WH5 for larger volume flows must be designed separately.

Construction

The droplet separator unit of the air washer is equipped with a quick-release fastener. The continuously fed spray nozzles for wetting the packing unit are located on lances that are flange-mounted on the housing. This enables maintenance or inspection within a very short time. The installation direction of the droplet separator unit, right/left or upwards when viewed in the air direction, is adapted to the local conditions.

How it works

VAKUTEC® air washers type WH5 work according to the principle of mass transfer. The impurities in the air flow are washed out in a contact chamber filled with packing material. The continuously sprayed packing unit increases the exchange surface required for mass transfer. The impurities in the air are transferred to the sprayed scrubbing liquid. The only moderate affinity to water is compensated for by increasing the exchange surface and contact time. The aerosols, carried by the air flow, then collide with the droplet separator packages. The liquid droplets are guided by the curvature of the profile to the inner surfaces of the profile and discharged into the catch pockets. In addition, sharp-edged elevations are attached to the surface of the louvre profile to remove the residual liquid. The droplet separator unit can optionally be equipped with a coagulator. The coagulator is placed between the droplet separator units and thus enlarges the very small droplets, which are then separated in the second separator unit. The collected liquid passes through a siphon, which prevents the intake of false air, or is fed directly back into the receiver tank via a dip tube.

Materials

The materials used depend on the specific physical and chemical loads that occur. Preferably, plastics such as PVC, PP and PVDF are used. In special cases, stainless steel profiles can also be used as droplet separator packages.

Technical data

With a uniform inflow, the air washer without coagulator enables 99% separation of a limiting droplet of approx. 15µ at a pressure loss of approx. 630Pa (length of the exchange section 1.000mm) or approx. 800Pa (length of the exchange section 1.500mm). With a coagulator, the separator performance increases to a limiting droplet of approx. 10µ at a pressure loss of 780Pa (length of the exchange section 1.000mm) or approx. 950Pa (length of the exchange section 1.500mm).

(The measured efficiency of the separation efficiency of a boundary droplet under laboratory conditions with water at 20° C)

Detailed catalogue with characteristic curves and dimension sheets

Deutsch (Deutschland)

Deutsch (Deutschland)  English (United Kingdom)

English (United Kingdom)