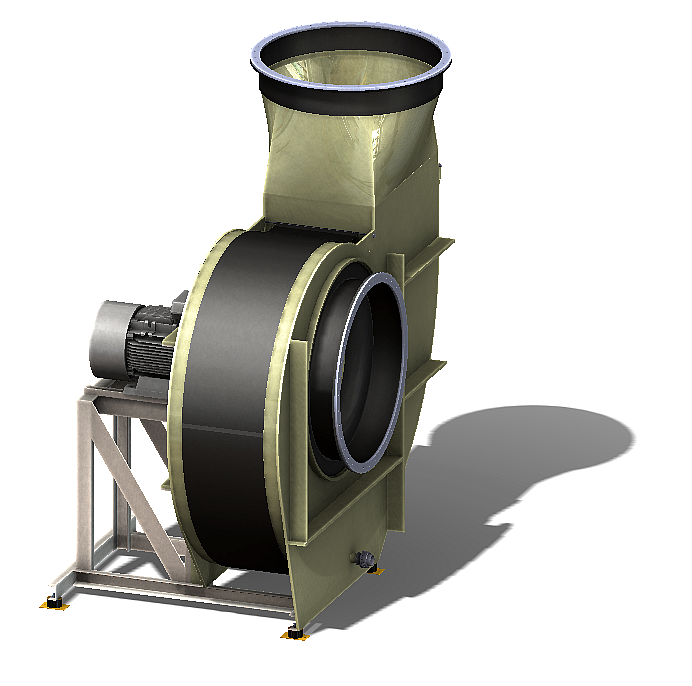

VAKUTEC® - radial fany Typ BM3 (SM3)

Size and power range:

VAKUTEC® - high-performance centrifugal fans for the medium pressure range with the type designation BM3 are manufactured in 15 different sizes according to DIN 323 Part 1, standard number series R20. For the nominal size DN200 to DN1.000 for air volumes of up to 63.000m³/h and a total pressure of up to max. 4.500Pa, you will find all the technical data shown in diagrams below. Larger fans up to DN1.600 are specifically designed according to the existing operating conditions.

Materials:

Depending on the physical and chemical operating conditions, the following materials can be selected:

Fan housing: PVC, PP, PE, PPs, steel, painted steel and stainless steel

Impellers: PVC, PP, PVDF, steel-coated, rubberised steel and stainless steel

Drives: The drives can be supplied with V-belts, direct, direct with block bearing and coupling and frequency inverter, depending on your requirements.

As the fan housing and impeller are compatible with each other, an optimum combination is available for every application.

Housing and housing position

The housings are designed in a stable welded construction and reinforced in accordance with the static requirements.

Impellers

The impellers are manufactured with 6 backward-bent blades as standard and are statically and dynamically balanced in accordance with VDI guideline 2060, quality group Q 6.3. Economical operation is guaranteed by high efficiency levels.

Drives and motors

The impeller can be driven directly up to almost all sizes. Indirect drive is possible for all sizes and is then carried out via a narrow V-belt drive, which is protected against contact in accordance with accident prevention regulations.

The standard bearing is a maintenance-free flanged double bearing; larger types can be equipped with pedestal bearings/block bearings and couplings according to customer requirements.

Bearings with permanent grease lubrication, designed for a theoretical service life of approx. 20.000 operating hours, are used as standard, but a design with relubricatable bearings is also possible in accordance with customer requirements.

To ensure optimum operation of the unit, all drive motors are adequately dimensioned. Externally cooled three-phase cage motors with protection class IP 55 are predominantly used, multi-stage and explosion-protected if necessary. With indirect drive, the motor is either attached to the frame structure or, in the case of larger units, it is mounted on a clamping device. The belt drive and drive motor are aligned with the fan axis so that the narrow V-belt drive is tensioned over the shortest possible distance and the vibration dampers are loaded evenly. On request, the motor can be fitted with a weather protection cover for outdoor installation.

The base frame and fan stand form a single unit made of profiles in a solid welded construction. The base coat and protective coating are in the colour RAL 9006.

Detailed catalogue with characteristic curves and dimension sheets

Deutsch (Deutschland)

Deutsch (Deutschland)  English (United Kingdom)

English (United Kingdom)