Durable & robust products for trouble-free operation

The manufacturing of our products is always oriented towards the current state of development and manufacturing technology as well as the growing requirements of the approving authorities. At the same time, we strive to permanently improve function, quality and the price/performance ratio through innovations and optimisation of production. In doing so, we remain true to the principle of producing "durable & robust products for trouble-free operation".

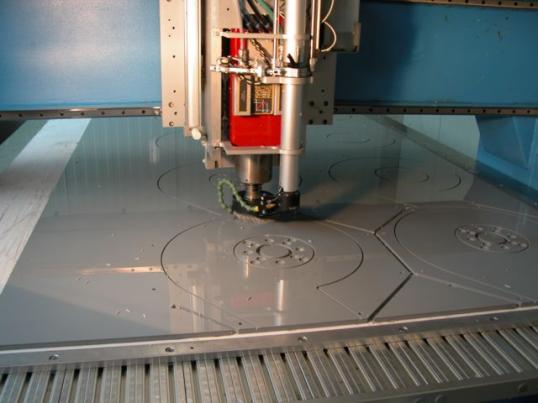

Products and components are designed at CAD workstations using SolidWorks and AutoCad®, which ensures loss-free data exchange with customers and suppliers. The components for the CNC machining center are created in the CAM system.

The core of production is the CNC machining center. The components developed in the design are CNC milled from semi-finished products/plate material with consistently high accuracy and quality.

Steel structures for our fans and their impellers are manufactured in our own metalworking shop and then painted in-house. After balancing, the steel wheels are given a corrosion-resistant coating by long-standing suppliers.

During final assembly, the components produced by the various departments and the other built-in parts are assembled into the final product.

All products are then subjected to in-house quality management and documented. Our fans are only delivered after a successful test (test run/vibration measurement).

Deutsch (Deutschland)

Deutsch (Deutschland)  English (United Kingdom)

English (United Kingdom)